Nā huahana

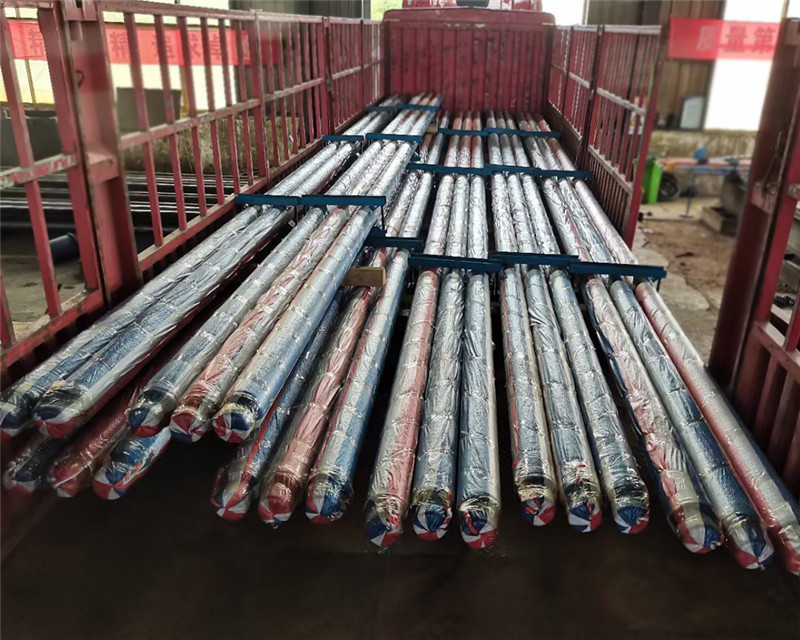

ʻO nā Collar Drill Non-Magnetic & subs

Kola Drill ʻAʻole Magnetic

Slick Non-Mag Drill Collar

Hāʻawi ka Slick Non-Mag Drill Collar i ke kaumaha i koi ʻia ma ka bit, a ʻaʻole e hoʻopilikia i ka hiki ke hoʻoheheʻe kuhikuhi.

Spiral Non-Mag Drill Collar

Hoʻolālā ʻia ʻo Spiral Non-Mag Drill Collar e ʻae i ka wahi kahe nui no ka hoʻoheheʻe wai, ʻoiai e hāʻawi ana i nā pono o ke kila non-mag no nā papahana wili paʻakikī.

Flex Non-Mag Drill Collar

ʻOi aku ka lahilahi o ka Flex Non-Mag Drill Collar ma mua o ke kola drill maʻamau. ʻO ko lākou hiki ke hoʻololi i ka radius pōkole, kūlou no nā kihi kūkulu kiʻekiʻe, a hele i nā dogleg koʻikoʻi e kūpono iā lākou no ka hoʻohana ʻana i nā noi kuhikuhi a me ka pae. Hana ʻia me ke kila non-mag, kūpono kēia kola drill no nā lako MWD hale.

Huahana Huahana

| Hoʻohui | OD mm | ID mm | Ka lōʻihi mm |

| NC23-31 | 79.4 | 31.8 | 9150 |

| NC26-35 | 88.9 | 38.1 | 9150 |

| NC31-41 | 104.8 | 50.8 | 9150 a i ʻole 9450 |

| NC35-47 | 120.7 | 50.8 | 915 a i ʻole 9450 |

| NC38-50 | 127.0 | 57.2 | 9150 a i ʻole 9450 |

| NC44-60 | 152.4 | 57.2 | 9150 a i ʻole 9450 |

| NC44-60 | 152.4 | 71.4 | 9150 a i ʻole 9450 |

| NC44-62 | 158.8 | 57.2 | 9150 a i ʻole 9450 |

| NC46-62 | 158.8 | 71.4 | 9150 a i ʻole 9450 |

| NC46-65 | 165.1 | 57.2 | 9150 a i ʻole 9450 |

| NC46-65 | 165.1 | 71.4 | 9150 a i ʻole 9450 |

| NC46-67 | 171.4 | 57.2 | 9150 a i ʻole 9450 |

| NC50-67 | 171.4 | 71.4 | 9150 a i ʻole 9450 |

| NC50-70 | 177.8 | 57.2 | 9150 a i ʻole 9450 |

| NC50-70 | 177.8 | 71.4 | 9150 a i ʻole 9450 |

| NC50-72 | 184.2 | 71.4 | 9150 a i ʻole 9450 |

| NC56-77 | 196.8 | 71.4 | 9150 a i ʻole 9450 |

| NC56-80 | 203.2 | 71.4 | 9150 a i ʻole 9450 |

| 6 5/8REG | 209.6 | 71.4 | 9150 a i ʻole 9450 |

| NC61-90 | 228.6 | 71.4 | 9150 a i ʻole 9450 |

| 7 5/8REG | 241.3 | 76.2 | 9150 a i ʻole 9450 |

| NC70-97 | 247.6 | 76.2 | 9150 a i ʻole 9450 |

| NC70-100 | 254.0 | 76.2 | 9150 a i ʻole 9450 |

| 8 5/8REG | 279.4 | 76.2 | 9150 a i ʻole 9450 |

Mea hoʻopaʻa hoʻopaʻa magnet ʻole

Hana ʻia ka mea hoʻopaʻa hoʻopalekana non magnetic mai hoʻokahi hoʻopaʻa paʻa ʻana o ke kila kila ʻole. ʻO ka mea maʻemaʻe kiʻekiʻe Chromium Manganese Austenitic stainless steel.

Ultrasonic inspection a me MPI inspections ua hana ia ma kela a me keia forging ma luna o kona piha lōʻihi a me ka pauku, ma hope o ka machining 'oʻoleʻa e like me API Spec 71. Mill ho'āʻo palapala hōʻoia me ka mechanical waiwai, kemika kālailai, magnetic waiwai a me nā inspections ua lako me nā stabilizers a pau.

Loaʻa iā mākou ka hiki ke hana i ka Non Magnetic Stabilizer a hiki i ka Crown OD 26 ''

Huahana Huahana

| Ikaika U'i | Ka ikaika hua | ʻoʻoleʻa | Mākēneki Permeability | |

| min. | min. | min. | MAX | Awelika |

| 120KSI | 100KSI | 285HB | 1.01 | 1005 |

Non Magnetic MWD Sub

Hana ʻia ka Non Magnetic MWD Sub mai ka Chromium Manganese Austenitic stainless steel, compressive stress resistance pipe i hana ʻia mai nā mea ʻole no ka hoʻokomo ʻana i ka impulser MWD i loko a me nā mea ʻē aʻe. Ua hoʻohana nui ʻia ka Non Magnetic MWD Sub e nā ʻoihana hoʻoheheʻe alakaʻi kūloko a me ka honua.

Hoʻopili ʻia nā mea pili a pau e like me ka API Spec.7-2 a ua hana anu nā aʻa kaula a uhi ʻia me ka hui ʻana o ke kaula API a hoʻolako ʻia me nā mea pale.

Huahana Huahana

| Anawaena (mm) | Anawaena Kuloko (mm) | Ka lōʻihi o loko (mm) | ʻO ka hope haʻahaʻa puka hāmama (mm) | huina pau (mm) |

| 121 | 88.2 | 1590 | 65 | 2500 |

| 172 | 111.5 | 1316 | 83 | 2073 |

| 175 | 127.4 | 1280 | 76 | 1690 |

| 203 | 127 | 1406 | 83 | 2048 |

LANDRILL Non Magnetic Materials standard

ʻAʻohe Magnetic Properties:

Pili Pahu: Max 1.005

Wahi Wela / Kahua Māla: MAX ±0.05μT

Hana Kūikawā ma ID: Roller Burnishing

Ma hope o ka puhi ʻana i ka wili, hiki mai kahi papa compressive, ʻo nā mea maikaʻi penei:

E hoʻonui i nā waiwai pale corrosion, E hoʻonui i ka paʻakikī o ka ʻili a hiki i HB400, E hoʻonui i ka hoʻopau ʻana o ka ʻili i Ra≤3.2 μm, Hoʻāʻo a nānā ʻia i kēlā me kēia pā i ka wā o ka hana ʻana o nā ʻāpana NMDC, Stabilizer a me MWD.

Ka Hoʻohui Kemika, Hoʻāʻo Tensile, Ho'āʻo Hoʻopaʻa, Ho'āʻo Paʻakikī, Ho'āʻo Metallographic (Ka nui o ka palaoa), Ho'āʻo Corrosion (E like me ka ASTM A 262 Practice E), Ho'āʻo Ultrasonic ma luna o ka lōʻihi holoʻokoʻa o ka pā (E like me ka ASTM A 388), Relative magnetic Ka ho'āʻo permeability, Hōʻike Hōʻike wela, Nānā Manaʻo, etc.

ʻO nā koho lapaʻau kūikawā kūikawā: Peening Hammer, Rolling Burnishing, Shot Peening.

Keena 703 Hale B, Greenland kikowaena, Hi-tech development zone Xiʻan, Kina

Keena 703 Hale B, Greenland kikowaena, Hi-tech development zone Xiʻan, Kina 86-13609153141

86-13609153141